In order to draw proper conclusions about the quality and technological properties of foods being tested with an RVA, intrinsic and extrinsic factors must be taken into account: Finally, the power required by the motor correlates directly with the apparent viscosity. Depending on the product, the test can take 2–15 minutes to be completed. An aluminum sample container is filled with a certain mass of powdered product and volume of water, and placed to surround the paddle, after which the motor is started.Ī metal conductor at high temperature (>90☌) rapidly heats the mixture until the sample reaches the gelatinization temperature of the starch. 3 ApplicationĪ Rapid Visco Analyzer consists of a stirring paddle attached to a motor whose shaft rotates at constant speed, and the current (energy) required to drive it is monitored continuously by a microprocessor. The viscosity changes produced when heating and cooling the starch in water allows determination of the minimum energy required to cook and process the sample/product being tested, and the appropriate conditions for desired consistency and thickening effect.Īn RVA is also a practical and important baking quality indicator, since there is a tight relationship between rheological and mixing properties of flour/water mixtures, e.g., dough strength/torque, water absorption, shear and temperature stability, falling number, and dough extensibility all of them correlating with each other. It allows for the physical characterization of flour-based products.

RelevanceĪn RVA is an important R&D tool.

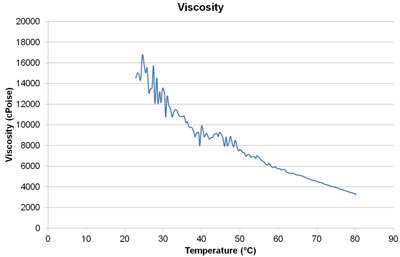

The obtained curve of the sample as a function of the apparent viscosity, temperature, shear stress, and time, allow to visualize the points where physical transitions and changes in the texture of the sample take place (e.g., gelatinization, retrogradation and re-ordering of starch molecules, and formation of final viscous gel/paste). The RVA device has a software that allows recording and plotting of the behavior (curve) of the product being analyzed as a function of temperature (☌), analysis time (min), and apparent viscosity (cP-Centipoise).

0 kommentar(er)

0 kommentar(er)